Jinwell Machinery EVA/POE photovoltaic film production line has maintained a certain market share in the world, while maintaining close contact with the head factory of photovoltaic film enterprises, for decades, Jinwell Machinery has produced hundreds of EVA photovoltaic film machinery used in the photovoltaic industry, and the equipment has been updated and iterative many times. Both the structure of the equipment and the commissioning process have been polished for decades, forming a mature production system for the photovoltaic industry, which can provide customers with a full range of services from raw material procurement, formula consulting, related auxiliary equipment, commissioning process training and so on.

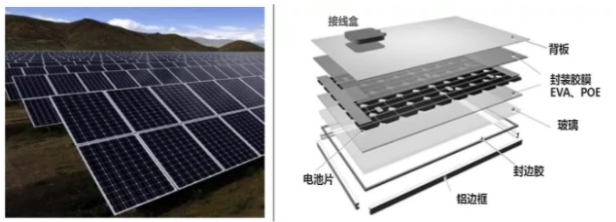

EVA solar cell film is used for solar cell packaging. After laminating and curing, it is bonded and sealed. It plays a role of high light transmittance, preventing water vapor penetration, high and low temperature resistance, and ultraviolet light resistance to the battery module, ensuring the stable and efficient use of the battery module.

Jinwell EVA film production line Performance characteristics:

(1) The extrusion part is designed as a large diameter single screw, and the screw barrel is cooled by circulating water, which can solve the problem of EVA not plasticizing and not cross-linking, and also ensure the good quality of the product.

(2) The roller body part adopts double-sided embossing, and solves the technical difficulties of the film sticking roller. At the same time, we can customize embossing patterns according to customers' needs, and can also provide customers with embossing patterns.

(3) An important factor for qualified EVA film products is the cooling shrinkage rate after the film is made, the service life of EVA film is usually set at 15-25 years, if the shrinkage rate of the product is not up to standard, it is likely to lead to the collapse of the solar panel after a long time because the internal stress is too large. Therefore, Kingwell machinery is specially designed to use cooling rolls and stress relief cold beds in the cooling part, so that the film runs smoothly and is fully shaped to ensure that the shrinkage rate is less than 3%.

(4) The whole line adopts PLC automatic control, integrated into the HMI touch screen terminal, intelligent operation is extremely high to save labor costs.

(5) The production line is equipped with an online quality monitoring and control system to ensure the product pass rate.

(6) The micro-tension winder can make the line speed of the whole machine production line reach 18m/min, and can minimize and cut off the tension of the take-up and take-up parts without an energy storage device

There is no phase difference in the film mite part, which can inhibit the grain in the winding and the deviation of the film.

The system can narrow the film during the automatic cutting action.

The market for photovoltaic film is expected to triple in the next five years. The technology change promotes the continuous increase of module power leading to the gradual dilution of the consumption of single GW module, but the installed capacity of the terminal still maintains a rapid growth trend, photovoltaic film is increasing year by year, it is expected that the demand for photovoltaic film will reach 5 billion square meters in 2025, and the CAGR will be 20% in 2020-2025.

Three kinds of photovoltaic film application scenarios:

(1) Transparent and white EVA film: At present, single glass components usually use conventional transparent EVA film and white film for front and back packaging, white EVA film has high reflectivity, as the bottom film can effectively improve the battery gap incident light and the reflection of the transmitted light of the component, and improve the efficiency of the component 1W-3W.

(2)POE film: Due to the more serious PID attenuation problem of double-glass components and N-type batteries, EVA resin can be replaced with POE resin with better water resistance, weather resistance and transmission, and POE film is born.

(3) Multi-layer co-extruded POE film (EPE film, EVA/POE/EVA structure) : Due to the monopoly of POE resin by a few foreign petrochemical companies, the price is expensive, and more bubbles will be produced during component lamination, resulting in higher defect rate and lamination time, so Hai You new Material innovative research and development of multi-layer co-extruded POE film, so that it has both POE anti-PID performance and EVA high yield and lamination efficiency. And reduce the use of POE to achieve cost reduction and efficiency, and currently first-line component manufacturers are importing and using in batches.

Address of Factory Area 1: No.16, Donglin Lianfa Industrial Park, Guojia Road, Guojia Jing, Chengxiang Town, Taicang City, Suzhou

Address of Factory Area 2: No. 90 Shenfeng Road, Dafeng District, Yancheng City

Address of Factory Area 3: No. 69 Hongrong Road, Chongchuan District, Nantong City

Mobile phone: 18861955928 15906228589

E-mail: salep@gwell.cn xinws@gwell.cn lyq@gwell.cn

Scan code and browse on your phone

Follow WeChat official account